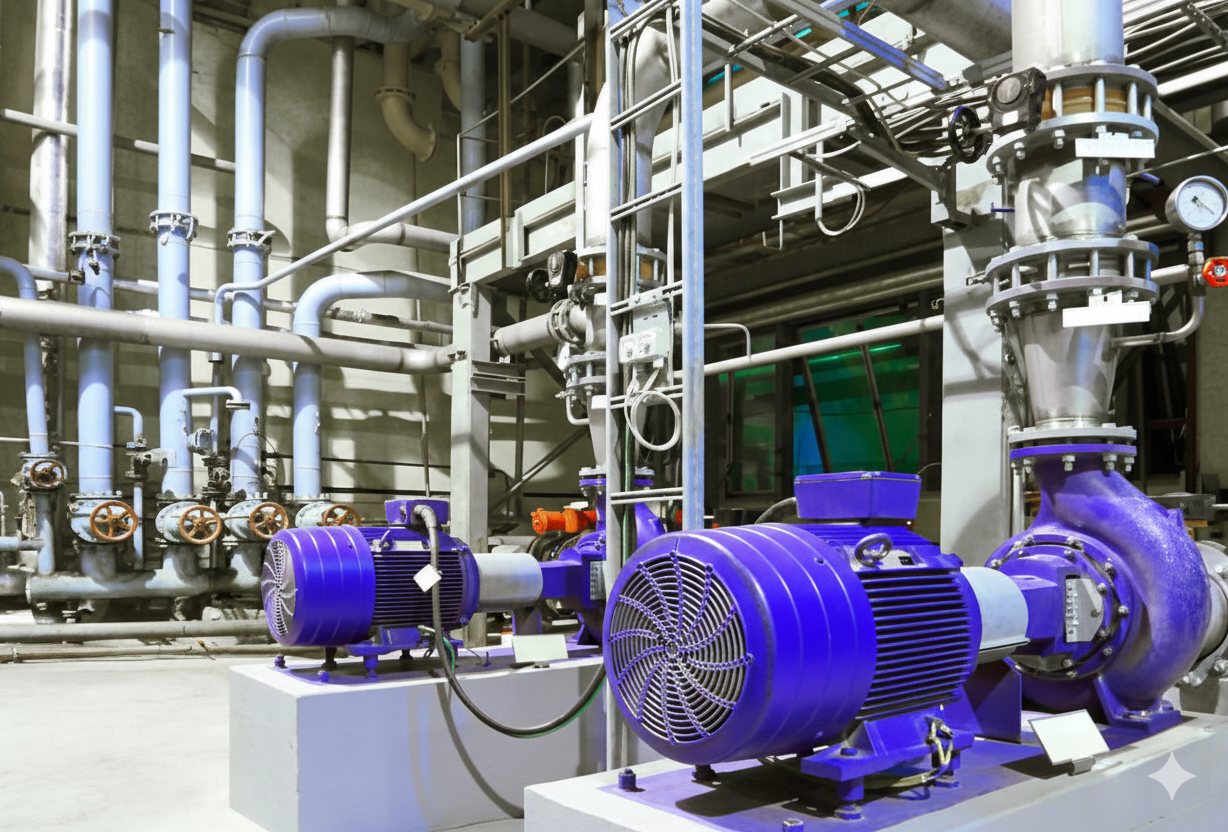

Electric motors are the backbone of industrial and commercial operations — from factories and plants to building maintenance systems in Gurgaon. These motors work tirelessly day after day, powering pumps, conveyors, HVAC systems, compressors, and more. Yet, many contractors and facility managers underestimate how much regular motor maintenance service can influence energy costs and operational performance.

Why Motor Maintenance Matters for Energy Efficiency

Motors that aren’t consistently maintained often experience increased friction, poor ventilation, and electrical imbalances. These inefficiencies force motors to consume more power to perform the same work as a well‑maintained motor, directly increasing energy bills and operational costs.

According to energy efficiency studies, an active motor maintenance program can lead to energy savings ranging from 2% to 30% of total motor system energy use when compared with neglected equipment.

This range is significant — even a modest 5–10% drop in energy usage across a facility full of motors can dramatically improve monthly utility expenses for factories, warehouses, and large buildings.

How Maintenance Improves Operational Performance

1. Optimizes Motor Efficiency:Regular servicing — including cleaning, lubrication, alignment checks, and tightening electrical connections — helps motors operate close to their designed efficiency. When resistance and friction are minimized, the motor draws less current while delivering the required torque and power. This not only lowers energy consumption but ensures smoother performance.

2. Reduces Unplanned Downtime:Motors running inefficiently are more prone to breakdowns, which disrupt production and lead to costly emergency repairs. Preventive maintenance identifies early warning signs like vibration, overheating, or worn parts, allowing technicians to address issues before they lead to catastrophic failure.

3. Extends Motor Life:A well‑maintained motor experiences less wear and tear. By replacing worn bearings, ensuring proper insulation, and maintaining balanced voltage supply, motor components remain in better condition for longer, delaying the need for pricey replacements or rewinding services.

Quantifying the Energy Savings

Consider this: a maintenance routine that cuts motor energy consumption by just 10% can immediately reflect in lower electricity bills — especially for facilities where electric motors account for a large share of total energy use.

Additionally, proper alignment and reduced mechanical drag can save up to 2–10% of energy wasted due to misalignment and friction losses.

When these savings are aggregated across multiple motors in an industrial setup, the cumulative effect becomes a powerful contribution to operational efficiency and cost control.

Benefits Beyond Energy Bills

The advantages of regular motor maintenance aren’t limited to energy savings:

- Better Equipment Reliability: Motors that run efficiently are less likely to cause disruptions in production or service cycles.

- Improved Safety: Proper maintenance ensures that electrical faults and mechanical wear do not become safety hazards.

- Lower Long‑Term Costs: Reducing energy waste and preventing major failures diminishes the lifecycle cost of motors, giving facility managers greater control over budgets.

A Smart Decision for Local Businesses in Gurgaon

For contractors, building managers, and industrial clients in Gurgaon, implementing a regular motor maintenance service is not just good practice — it’s a strategic decision that boosts performance and protects your bottom line.

By choosing a proactive maintenance plan, you can:

- Cut energy expenses significantly, often up to around 30% on individual motor systems with comprehensive care.

- Minimize unexpected downtime and production losses.

- Maximize the return on investment from your existing mechanical assets.

Conclusion — Don’t Wait for Failure to Strike

Neglecting motor maintenance is like ignoring a slowly rising cost on your energy bills. The sooner you adopt a structured maintenance approach, the faster you’ll notice improvements in performance, reliability, and cost savings.

📞 Ready to reduce energy costs and improve motor performance in your facility? Contact our expert motor maintenance team in Gurgaon today to schedule a complete inspection and tailored maintenance plan that fits your business needs!